Dry dope-free premium connections: a zero discharge technology validated through laboratory and field testing and usage

Tomás Horacio Castiñeiras A , Koji Sakura B and Bruno Giacomel CA Tenaris Technical North Sea Godesetdalen 10 Stavanger Norway

B Tenaris Technical Asia Pacific 1-10 Minamiwataridachou Kawasaki Ku, Kawasaki 210-0855 Japan

C Tenaris Technical Oceania Level 2 Talbot House 83 Havelock Street West Perth WA 6005

The APPEA Journal 49(2) 603-603 https://doi.org/10.1071/AJ08076

Published: 2009

Abstract

Dope-free alternatives to standard thread compounds used for casing and tubing connections became commercially available around 2003. The challenges from galling resistance needs and handling and storage requirements were addressed. The lessons learnt from the initial uses and experiences with the dope-free solution were incorporated into products that are reliable and have proven their suitability in environments that vary from the extremely humid and cold North and Barents Seas to the sandy and hot environment of the Middle East. The experiences to date not only confirm the validity of initial drivers —mainly related to the environmental care—for the development of these alternatives, but also open up the possibility of the complete elimination of thread compound from the casing and tubing installation and storage processes.

The dope-free solution has demonstrated suitability for application in all tubing and casing dimensional size ranges including: all type of steels (such as common carbon steel—both API grades and proprietary), 13Cr, and corrosion resistance alloys (CRA), premium connections with metal-to-metal seal both threaded and coupled (T&C), as well as integral connections. Experience with large outside diameter (OD) semi-premium connections indicates that this can be another area of application for dope-free solutions. This paper describes the different experiences related to the field use of dry, dope-free solutions, the improvements and adjustments incorporated after initial experiences and operators feedback and the verification activities in laboratory and especially in experimental rigs under actual field conditions. The intention of this presentation is to present the advantages and the value obtained through the use of this technology.

keywords: Dope-free, Dopeless, HSE, casing, tubing, premium connections

Introduction

The use of API threaded connections and proprietary premium connections for tubing and casing pipes in the oil and gas industry has been linked in the past to the need for some particular dope or thread compound to guarantee proper thread engagement, to assure that no damage occurs on the threaded surface, and to provide limited sealing at least in standard Rounded or Buttress API connections.

This extended abstract describes the development and field experience related to a particular fully dry dope-free technology that has undergone extensive development in the laboratory and now has been fully proved in different environments varying from very cold weather offshore applications to very hot sandy onshore operations.

Potential problems or risks are also evaluated and discussed.

The basic design, laboratory development, experimental rig evaluations and the extended field verifications form an extensive package that allows a major shift in rig operations: the doping of premium connections during running operations of rigs is no longer required.

The dry dope-free solution adopted and described in this paper (Dopeless®) is an engineered combination of multiple layers that aims to provide key benefits and advantages during pipe assembly even under harsh conditions. The coating was developed to assist the connection assembly by providing the required tribological properties. The connection can be subjected to repeated assembly (make-up) and dis-assembly (break-out) operations without the need of re-application of any lubricant with consistent make-up performance even exceeding that for one of connections assisted with thread compounds.

No removal of storage compound is performed. The Dopeless® coating is applied at the mill facilities and no treatment is required until field running, leading to a ready-to-be-used connection. Through strict process quality control, lubrication and corrosion resistance are guaranteed.

R&D on Dope-Free Connections – from the Laboratory to the Field

Prior to the commercial launch of Dopeless® solution in 2003, extensive research and development around dope-free technology was carried out. All potential demands and requirements for a dope-free solution for connection assembly were surveyed.

A simple and efficient testing scheme was developed in order to characterise, reformulate, discard, verify and validate any new potential dope-free solution for oil and gas pipe connections. Several types of coatings have been evaluated, aiming for an optimum balance on frictional performance, galling resistance, storage capability and industrial deployment.

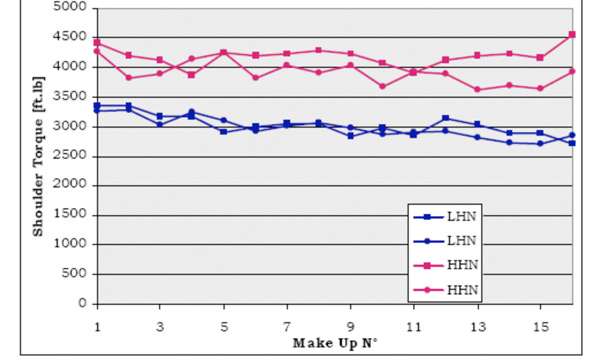

Coatings that have shown good corrosion resistance and frictional properties have been subjected to full-scale test to determine their suitably as a potential dope-free solution in real full-scale connections. Repeated assembling and disassembling operations (Make and Break [known as M&B] test) have been performed in order to evaluate the tribological properties and galling resistance of the coatings.

Several coatings were tested through full-scale tests. Some coatings showed friction consistency during the successive M&B operations.

Figure 1 shows how a coating looks like after being subjected to 15 M&B operations. Some coatings had poor performance, such as high friction, premature wear, inability to maintain a constant shoulder torque value.

|

Thus these coatings were discarded as potential dope-free solution or were reformulated after a study to determine the main cause of this poor performance. This is a valuable stage since deep knowledge of the coating and its interaction with the connection was acquired. A reformulated coating was tested again from the beginning of the testing process.

Coatings with good full-scale performance were further tested on full-scale samples aiming to determine their behavior on the exposure to real situations. Therefore, corrosion resistance in outdoor storage (yard), autoclave and immersion tests were carried out.

Outstanding performance of a dope-free solution is not only limited to M&B under the most demanding environmental conditions, but also has to be demonstrated that it has no detrimental effect on connection performance under combined load test.

Quite apart from the extensive and complete laboratory developments and verifications that can be done, it is important to recognise the difficulties of reproducing all the possible field scenarios and conditions that could affect the coating/connection performance. Field trials under controlled conditions are considered a key element in the validation process of dope-free coatings and connections. To cover this need, an experimental rig was rented for testing new coating developments, improvements and applicability in new connections. In addition to typical M&B evaluations that are affected by pipe weight and inertia, some other running conditions can be simulated with the aim to validate the product performance and robustness under tough real conditions.

Conclusions

After five years of field deployment in difficult and diverse environments, it is possible to confirm that dope-free technology has a real possibility of becoming a new standard in the oil and gas market, eliminating the need of using poorly controlled, compositionally diverse and environmentally aggressive thread compounds.

The technology has evolved since the initial introduction in 2003. The key improvements have beeen: better storage capacity through improved corrosion resistance and achieved by improved coating design and the development of improved thread protectors; lessons learned on frictional issues and problems in the field related to make up or break out operations, that have been solved through further research and optimisation. Extensive validation has been achieved by the use of this dope-free alternative in different field and weather conditions, for different sizes and grade combinations.

Acknowledgements

This abstract and its associated presentation is based partially on a SPE paper published by Tenaris (SPE/IADC 119642Dry Dope-free OCTG Connections: A novel Environmentally Friendly Technology Validated Through Diverse and Severe Field Conditions ). T. Castiñeiras, SPE, Tenaris; A. Núñez, Tenaris; E. Gallo, Tenaris; G. Carcagno, SPE, Tenaris

Tomás graduated with an honors degree in mechanical engineering in 1992 from the Instituto Tecnológico de Buenos Aires. He held a number of different technical and engineering positions in Tenaris Siderca, including plant maintenance, engineering and product design. In 1999 he moved to TenarisConnections as a regional manager for Latin America and in 2001 was assigned as responsible for major oil company accounts. In 2003 he moved to Houston and led the Tenaris dopeless project in the North Sea. From 2005 he has been the technical manager for Tenaris in Europe. tcastineiras@tenaris.com |

Koji Sakura graduated with a master’s degree in MechEng in 1979 from KEIO University Japan. He started his career with NKK in production technology before moving to London in 1991 as NKK Technical General Manager. In 1996 he was assigned the position of plant manager of NKK seamless department. Since 2000 Koji has held a number of senior management positions in the area of product design and quality control for TenarisNKKTubes. From 2007 Koji has held the position of Tenaris technical sales manager. ksakura@tenaris.com |

Bruno Giacomel graduated with a degree in Industrial Engineering in 2004 from the Instituto Tecnológico de Buenos Aires. In 2004 Bruno began his career with Tenaris Siderca as an oil and gas market analyst. Between 2005 and 2006 Bruno moved to the field working as a Field Service Engineer for the Argentine domestic market and internationally. In 2007 Bruno worked together with the Tenaris connections team while studying for his Masters degree in oil and gas. Bruno is now based in Perth as a technical sales representative for Tenaris Australia providing technical expertise for the Australia, New Zealand and Papua New Guinea markets. bgiacomel@tenaris.com |