A new analytical procedure to replace the outdated Weende proximal feed ingredient analysis paradigm is long overdue

Gene M. Pesti A *

A *

A

Abstract

Proximate analysis is also called the Weende method. It has been the standard used for describing the chemical composition of feed ingredients for the past 150+ years. Understanding of the chemical composition of feeds has changed greatly in that time. Most of the current terms used for proximate analyses are unclear and misleading: (1) Crude protein, nitrogen × 6.25 describes true protein plus any other nitrogen-containing compounds including nucleotides and even phospholipids. (2) Crude fibre represents approximately half of the true fibre in most ingredients, but only approximately one-seventh of the fibre in important ingredients like soybean meal. (3) Ether Extract represents the neutral lipids in ingredients but little of the polar lipids like the lecithins. (4) The Nitrogen-free Extract is not an extract at all. It is supposed to represent starch in feed, but it contains large proportions of pectin, hemicellulose and even some cellulose. It reflects the error in Crude Fibre. Inadequacies of the Weende system have been known for a very long time. Animal producers desire to embrace modern technology and adapt more precise feeding techniques.

This paper explains how 19th century chemistry relates to 21st century understandings of feed composition and proposes an updated method of feed ingredient analysis.

A new method of describing feed composition based on 13 modern chemical categories was conceived and called the ‘Armidale Method’, to distinguish it from the Weende method. The new feed chemical category method was used to compile a preliminary database based on: moisture, sugars, oligosaccharides, starch, pectin, hemicellulose, cellulose, lignin, ash, neutral lipids, polar lipids, true protein, and nonprotein nitrogenous compounds.

Composition values for 26 ingredients compiled from three sources averaged 1032.0 ± 49.5 g/kg, comparable to the theoretical 1000 g/kg.

The Armidale Method of analyses could be the starting point for discussions of new standardised procedures for ingredient trade and feed formulation.

It is time for producers, in conjunction with nutritionists and analytical chemists, to explore the best ways to represent the composition of feed ingredients for feeding value and trade.

Keywords: Armidale method, crude protein, feed analysis, food analysis, paradigm, proximate analysis, true protein, Weende method.

Introduction

Thomas Kuhn, writing in his book The Structure of Scientific Revolutions (1970) used the term ‘paradigm’ to describe the theoretical assumptions, laws and techniques that dominate scientific experimentation by a particular community of scientists during a given period.

Eventually, however, observations that are at a variance with the current paradigm are encountered. The paradigm is recognised as being inadequate and a new and radically different hypothesis is proposed, usually coupled with new methods. This leads to a new paradigm and a period in which it is consolidated follows. (Carpenter et al. 1997)

Most of nutrition science has progressed by following closely behind the advancement of analytical chemistry techniques and understanding the digestive physiology of animals. One exception has been in estimating the composition of feed ingredients. The paradigm for describing the composition of feed ingredients for animals (including poultry) has been based on the Weende method, or proximate analysis (Severe 2022). These analytical techniques were first introduced in the Hanover Kingdom in the city of Weende in 1864, long before the true chemical nature of feed ingredients was known. Specific techniques for analysing feed using the Weende method were first published by the United States Department of Agriculture in 1888 (Richardson 1888). Tradition and government regulations may best explain why the Weende method is still being used (Mariotti et al. 2008).

In this paper the limitations of the proximate analysis system are discussed and a new Feed Chemical Category analysis method for feed, the Armidale Method is outlined. To make the case for the replacement of the Weende method, a preliminary feed ingredient database based on the Armidale Method is compared to a Weende method database.

Weende and Armidale methods described

Many observations are at variance with the proximate analysis system paradigm for representing feed composition differences related to nutritional responses. Crude measures do not represent current understanding of feed composition. Specific variances are very well known and accepted and have been very nicely detailed by Wardeh (1981) and so will only be paraphrased here:

Crude fibre (CF) is thought to contain the less digestible portion of feed ingredients. It is measured as the residue left after extraction with boiling dilute alkali and acids.

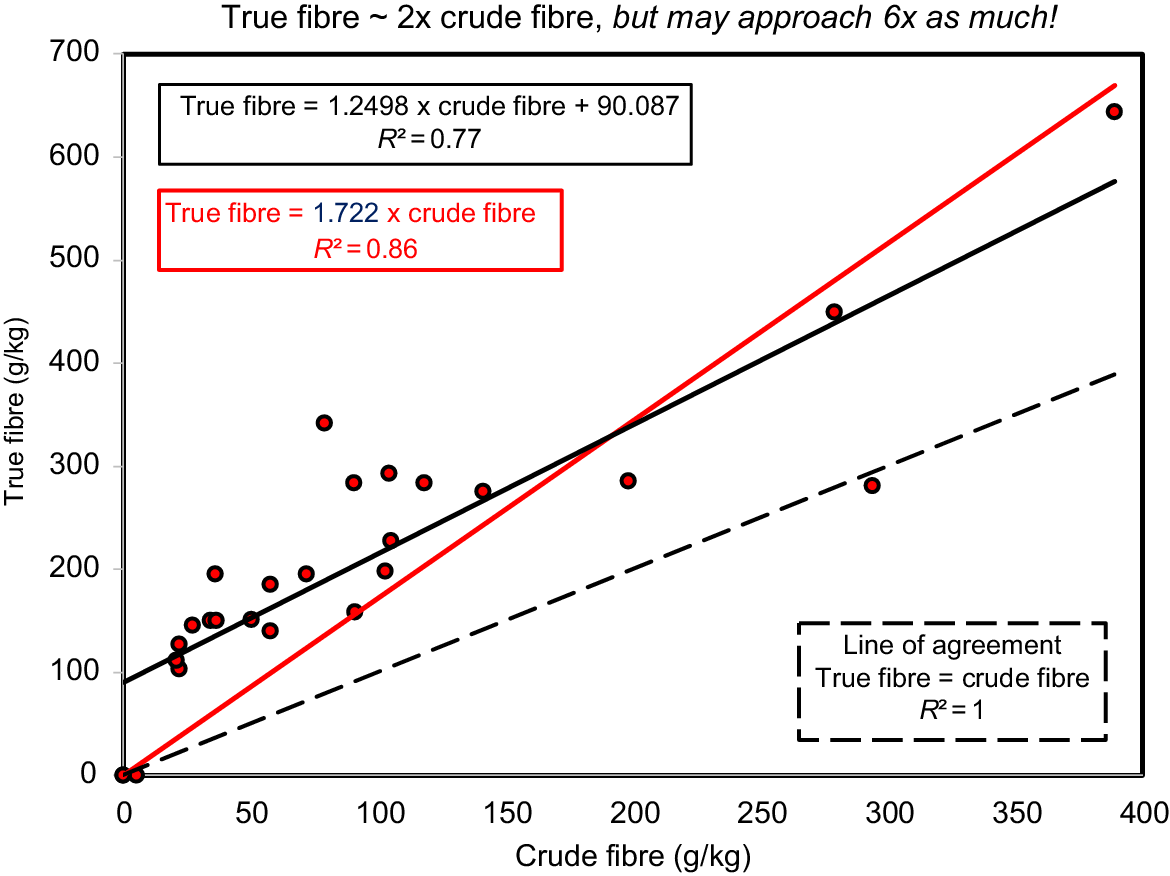

There is variation from different boiling temperatures due to different altitudes of various laboratories. This residue is now known to contain cellulose and portions of hemicellulose and lignin (Fig. 1).

The Nitrogen-free Extract (NFE) has been found to be less digestible than crude fibre in some feeds.

Fine grinding can cause underestimation of both crude fibre assays and digestibility of fibre.

Ethyl ether does not extract all lipids, and it extracts some substances with little or no feeding value.

Crude protein does not differentiate between different forms of nitrogen.

Nitrogen-free Extract (NFE) is supposed to comprise readily available carbohydrates, sugars, oligosaccharides, and starches, but also contains much of the pectin, hemicellulose, and lignin.

Ash, as determined by the ignition method, contains some carbonates and sulfates with the oxygen coming from the air, and trapped carbon molecules. Other minerals, particularly chlorine, iodine, selenium, iron, phosphorus, and silicates may be volatilised and lost upon ashing. The temperature balance point for absorption versus volatilisation is different for different ingredients.

The relationships between true and crude fibre for 26 commonly fed feed ingredients for poultry. All the observed points apply to both lines. The solid lines represent lines fitted with and without an intercept. The dashed line crossing the y-axis at zero represents perfect agreement between true and crude fibre.

There are other problems with the Weende method not included by Wardeh (1981). One is the double counting of nitrogenous compounds as crude protein and lipids. In 1864 it was not known that there were ether soluble compounds, like lecithin, that also contain nitrogen.

For some time, several laboratories have been studying the feeding values of various carbohydrate fractions in feed ingredients (Choct 2015) and the use of the true protein levels of feeds to satisfy the dietary dispensable (nonessential) amino acids (Sriperm et al. 2011; Alhotan and Pesti 2016). From many studies, it became obvious that the 19th century paradigm for describing feed ingredients was obsolete.

To explain to students what 19th century feed composition chemistry really means, the ‘Armidale Method’ is presented, named in reference to the city where it was conceived (Pesti et al. 2024; Fig. 1). The Armidale Method categorises the various nutrients into definable chemical entities consistent with modern chemical knowledge: moisture, sugars, oligosaccharides, starch, pectin, hemicellulose, cellulose, lignin, ash, neutral lipids, polar lipids, true protein, and nonprotein nitrogenous compounds.

It is time for food animal producers to convene a group to study the next steps toward a new paradigm for describing the chemical composition of feeds and feed ingredients. The scientists involved should include nutritionists, analytical chemists, and feed manufacturing specialists. Because many producers make their own feed, government regulations should not be a major impediment as they are for human food manufacturers (Mariotti et al. 2008). Government regulations should follow science, not the converse.

Weende and Armidale methods compared

The Armidale and Weende method data were compiled mainly from the Australian Feed Ingredient Database (Moss 2020). In addition to analytical data on the carbohydrate fractions of many feed ingredients commonly fed around the world, the database contains total and digestible amino acid and ether extract levels. Sugar, and lignin (a polyphenolic compound), were not covered in said database and hence values were from the Feedipedia (2024) database. Polar and nonpolar lipid proportions were from the values of Weihrauch and Son (1983). Any missing data were from an Australian feed manufacturer. Slopes and coefficients of determination (R2) were computed using Microsoft Excel (Table 1).

| Category | Building blocks | Typical units | Proximate analysis | GE (kJ/g) | Potential digestibility | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | CF | Ash | EE | NFE | ||||||

| Sugars | Hexoses | 1–2 | ✓ | 16.74 | 1.00 | |||||

| Oligosaccharides | Simple sugars | 3–12 | ✓ | 16.74 | 0.90 | |||||

| Starch | Glucose | >12 Variable | ✓ | 17.57 | 100.00 | |||||

| Pectin | Galacturonic acid, 80% methylated | 300–600 | ✓ | 15.56 | 0.70 | |||||

| Hemicellulose | Pentosans | ✓ | ✓ | 16.74 | 0.50 | |||||

| Cellulose | Glucose | 300–10,000 | ✓ | 16.74 | 0.10 | |||||

| Lignin | Heterogenous phenolic compounds | >60 | ✓ | ✓ | 25.50 | 0.00 | ||||

| Ash | Minerals | ✓ | 0.00 | 0.00 | ||||||

| Neutral lipids | Triacylglycerides, waxes, resins, chlorophyll, etc. | 1 | ✓ | 39.75 | 100.00 | |||||

| Polar lipids | Phospholipids | 1 | ✓ | ✓ | 31.00 | 100.00 | ||||

| True protein | Amino acids | >20 | ✓ | 23.85 | 100.00 | |||||

| NPNC | Nucleotides etc. | ✓ | 24.59 | 97.00 | ||||||

CF, crude fibre; CP, crude protein; EE, ether extract; NFE, nitrogen-free extract; NPNC, nonprotein nitrogenous compounds; GE, gross energy.

The feed ingredient compositions totalled 1030.3 ± 49.5, surprisingly close to 1000 g/kg, considering that the databases contain averages for many ingredients (Table 2). The lowest value was 980 g/kg for Meat and Bone Meal, which had an obvious problem since the value for nitrogen-free extract (NFE) was negative (Table 3).

| H2O | Ash | Lipids | True protein | Saccharides | Lignin | Pectin | Hemicellulose | Cellulose | NPNC | Total | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Neutral | Polar | Mono- and Di- | Oligo- | Starch | |||||||||||

| Wheat | 103.3 | 13.0 | 12.9 | 7.1 | 107.0 | 23.4 | 19.9 | 632.0 | 9.9 | 0.0 | 92.5 | 24.8 | 4.6 | 1050.4 | |

| Sorghum | 115.3 | 14.2 | 28.9 | 7.0 | 96.7 | 14.0 | 9.5 | 647.1 | 9.7 | 0.0 | 59.8 | 33.8 | 0.3 | 1036.3 | |

| Triticale | 94.0 | 21.0 | 10.9 | 4.1 | 94.7 | 37.0 | 26.0 | 675.0 | 11.0 | 0.0 | 109.0 | 26.0 | 10.3 | 1119.0 | |

| Barley | 107.7 | 22.0 | 21.2 | 4.3 | 89.4 | 22.0 | 20.9 | 502.0 | 9.8 | 0.0 | 127.2 | 48.3 | 4.0 | 978.8 | |

| Maize | 112.5 | 12.5 | 37.4 | 2.3 | 83.0 | 17.0 | 0.7 | 621.0 | 1.2 | 0.0 | 83.1 | 27.8 | 2.7 | 1001.2 | |

| Oats | 120.0 | 27.0 | 48.4 | 16.0 | 84.3 | 16.0 | 8.9 | 389.3 | 25.0 | 0.0 | 175.5 | 83.1 | 9.2 | 1002.7 | |

| Millrun | 79.0 | 52.0 | 15.4 | 6.6 | 136.2 | 16.0 | 42.4 | 52.0 | 23.0 | 0.0 | 182.0 | 439.0 | 14.8 | 1058.4 | |

| DDGS (corn) | 110.0 | 54.0 | 104.5 | 6.5 | 266.0 | 16.0 | 46.3 | 93.0 | 25.0 | 0.0 | 206.0 | 111.0 | 29.0 | 1067.3 | |

| Soybean meal (local) | 120.0 | 64.2 | 0.0 | 19.5 | 414.6 | 63.0 | 78.5 | 5.5 | 0.5 | 0.0 | 0.0 | 195.6 | 42.3 | 1003.7 | |

| Soybean meal (Brazil) | 103.5 | 62.1 | 0.0 | 19.5 | 426.2 | 63.0 | 78.5 | 5.5 | 0.5 | 0.0 | 0.0 | 195.6 | 45.9 | 1000.3 | |

| SBM (US) | 100.5 | 64.8 | 16.8 | 0.0 | 418.1 | 108.0 | 78.5 | 63.0 | 4.0 | 45.5 | 0.0 | 101.0 | 45.6 | 1045.8 | |

| SBM (Argentina) | 100.4 | 65.6 | 17.3 | 0.0 | 418.5 | 108.0 | 78.5 | 63.0 | 4.0 | 45.5 | 0.0 | 101.0 | 45.6 | 1047.4 | |

| Full fat soy | 94.6 | 44.6 | 184.2 | 20.0 | 324.6 | 87.0 | 104.0 | 64.0 | 12.0 | 19.5 | 0.0 | 120.0 | 35.4 | 1109.9 | |

| Canola meal (cold) | 77.5 | 68.5 | 120.3 | 5.0 | 330.0 | 100.0 | 0.0 | 66.0 | 90.0 | 0.0 | 98.0 | 105.0 | 35.9 | 1096.2 | |

| Sunflower meal | 90.0 | 71.0 | 21.6 | 0.4 | 312.0 | 61.0 | 51.0 | 0.0 | 107.0 | 0.0 | 130.0 | 213.0 | 34.0 | 1091.0 | |

| Cottonseed meal | 101.0 | 69.6 | 28.2 | 3.1 | 375.7 | 46.0 | 29.2 | 0.0 | 54.0 | 0.0 | 53.4 | 90.8 | 40.9 | 891.9 | |

| Faba beans | 77.0 | 39.0 | 7.1 | 6.9 | 214.6 | 36.0 | 46.6 | 447.0 | 10.0 | 0.0 | 52.0 | 97.0 | 23.4 | 1056.6 | |

| Chickpeas | 70.0 | 33.0 | 15.0 | 35.0 | 192.1 | 36.0 | 57.5 | 356.0 | 7.0 | 0.0 | 0.0 | 221.0 | 20.9 | 1043.5 | |

| Lupins | 98.5 | 28.0 | 17.9 | 45.9 | 267.5 | 68.0 | 56.2 | 81.0 | 10.8 | 85.3 | 48.0 | 139.9 | 52.5 | 999.5 | |

| Peas | 108.0 | 26.3 | 12.0 | 7.3 | 182.3 | 42.0 | 38.7 | 413.3 | 3.6 | 0.0 | 60.7 | 75.8 | 35.0 | 1005.0 | |

| Copra meal | 97.0 | 68.0 | 58.8 | 10.4 | 196.2 | 11.4 | 78.1 | 9.0 | 67.0 | 0.0 | 253.7 | 190.6 | 21.4 | 1061.6 | |

| Palm kernel meal | 56.0 | 45.1 | 56.1 | 9.9 | 122.6 | 24.0 | 15.5 | 8.3 | 134.0 | 0.0 | 267.1 | 276.3 | 13.4 | 1028.3 | |

| Blood (ring dried) | 77.0 | 30.0 | 13.9 | 4.1 | 816.1 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 12.8 | 0.0 | 88.9 | 1042.8 | |

| Meat meal | 90.0 | 263.9 | 103.8 | 11.3 | 433.7 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 78.9 | 981.6 | |

| Meat and bone meal | 70.0 | 331.7 | 87.2 | 1.7 | 416.7 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 72.7 | 980.0 | |

| Average | 1032.0 | ||||||||||||||

| Standard deviation | 49.5 | ||||||||||||||

H2O, moisture; NPNC, nonprotein nitrogenous compounds.

| Ingredient | DM | H2O | CP | EE | Ash | CF | NFE | Total | |

|---|---|---|---|---|---|---|---|---|---|

| Wheat | 896.8 | 103.3 | 111.6 | 20 | 13 | 22 | 833.4 | 1000 | |

| Sorghum | 884.7 | 115.3 | 97 | 35.9 | 14.2 | 22.1 | 830.8 | 1000 | |

| Triticale | 906 | 94 | 105 | 15 | 21 | 27 | 832 | 1000 | |

| Barley | 892.3 | 107.7 | 93.4 | 25.5 | 22 | 57.5 | 801.6 | 1000 | |

| Corn | 887.5 | 112.5 | 85.8 | 39.7 | 12.5 | 20.9 | 841.1 | 1000 | |

| Oats | 880 | 120 | 93.5 | 64.4 | 27 | 90.5 | 724.6 | 1000 | |

| Mill run | 921 | 79 | 151 | 22 | 52 | 389 | 386 | 1000 | |

| Distillers Dried Grains with Solubles (corn) | 890 | 110 | 295 | 111 | 54 | 79 | 461 | 1000 | |

| Soybean Meal (local) | 880 | 120 | 456.9 | 19.5 | 64.2 | 72 | 387.4 | 1000 | |

| Soybean Meal (Brazil) | 896.5 | 103.5 | 472.1 | 19.5 | 62.1 | 36.1 | 410.2 | 1000 | |

| Soybean Meal (US) | 899.5 | 100.5 | 463.7 | 16.8 | 64.8 | 34.2 | 420.5 | 1000 | |

| Soybean Meal (Argentina) | 899.6 | 100.4 | 464.1 | 17.3 | 65.6 | 36.4 | 416.6 | 1000 | |

| Full fat soy | 905.4 | 94.6 | 359.9 | 204.2 | 44.6 | 50.3 | 341 | 1000 | |

| Canola meal (cold processed) | 922.5 | 77.5 | 365.9 | 125.3 | 68.5 | 104.4 | 335.9 | 1000 | |

| Sunflower meal | 910 | 90 | 346 | 22 | 71 | 279 | 282 | 1000 | |

| Cottonseed meal | 899 | 101 | 416.6 | 31.3 | 69.6 | 102.9 | 379.6 | 1000 | |

| Faba beans | 923 | 77 | 238 | 14 | 39 | 91 | 618 | 1000 | |

| Chickpeas | 930 | 70 | 213 | 50 | 33 | 105 | 599 | 1000 | |

| Lupins | 901.5 | 98.5 | 320 | 63.8 | 28 | 118.2 | 470 | 1000 | |

| Peas | 892 | 108 | 217.3 | 19.3 | 26.3 | 57.7 | 679.4 | 1000 | |

| Copra meal | 903 | 97 | 217 | 69.2 | 7 | 141 | 565.8 | 1000 | |

| Palm kernel meal | 944 | 56 | 136 | 66 | 183.2 | 198 | 416.8 | 1000 | |

| Blood (ring dried) | 923 | 77 | 905 | 18 | 30 | 5 | 42 | 1000 | |

| Meat meal | 910 | 90 | 512.6 | 115.1 | 263.9 | 0 | 108.4 | 1000 | |

| Meat and bone meal | 930 | 70 | 489.5 | 88.9 | 331.7 | 0 | 89.9 | 1000 |

DM, dry matter; H2O, moisture; CP, crude protein; EE, ether extract; CF, crude fibre; NFE, nitrogen-free extract.

The true fibre of the ingredients in the Armidale Method database (Table 2) averaged 3.2 ± 1.5 times higher than crude fibre (Table 3). However, wheat and maize, perhaps the two most important ingredients worldwide, had the biggest differences in true and crude fibre, with more than five times as much true as crude fibre (Fig. 1).

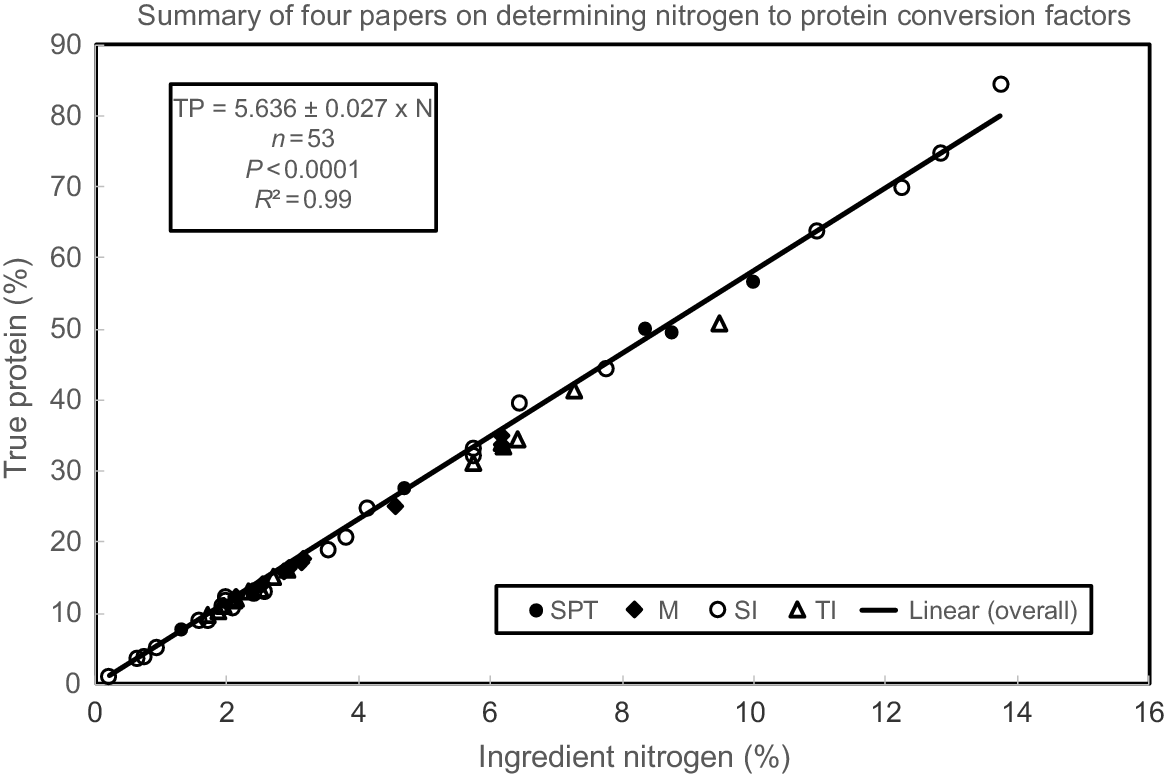

Similarly to true fibre and crude fibre, true protein is directly proportional to crude protein. However, the variation in true protein as a function of crude protein is much less than the analogous relationship between the fibre types (Fig. 2 versus Fig. 1).

The relationship between true protein and total nitrogen from four classic papers on feed ingredient protein to N conversion factors. Unpublished data from. [Data sources are SPT = Sriperm et al. (2011), M = Mossé (1990), SI = Sosulski and Imafidon (1990), TI = Tkachuk (1969) and Tkachuk and Irvine (1969)].

Distinguishing between polar and nonpolar lipids in the Armidale Method has the potential advantages of being able to distinguish between the energy contents and absorption of each type. The knowledge of the nitrogen content of polar lipids should prove particularly helpful for separating the energy contributions of phospholipids from crude proteins. Like the ability to assign different energy values to proteins based on their amino acid contents, knowing different lipid types will allow the assignment of different properties to the different lipid types. In the future, different lipids will surely be subdivided further based on unsaturation or melting temperature when such distinctions become helpful.

Discussion

Since 1864, there have been many advances in analytical chemistry, and knowledge about the chemical nature of feed ingredients has improved immensely. As analytical techniques for individual nutrients were developed, the new composition data was added to feed ingredient databases and nutritional requirements were determined and used in feed formulation. The exception was that proximate analysis remained the standard for food and feed analyses and trade. For instance, the ‘protein’ we see on food packaging in much of the world is not what is true protein, e.g. amino acid polymers. Food packaging protein is really crude protein, not consistent with modern definitions of protein, but including many other nitrogenous compounds (Krul 2019).

Proximate analyses are used in trading ingredients, and for predicting the energy value of feed ingredients. Mateos et al. (2018) compared eleven different systems for predicting the metabolisable energy of feed ingredients from proximate analysis. They found all the current systems to be inadequate for one reason or another. Their conclusion should not be surprising since the predictions were based primarily on crude protein, ether extract and nitrogen-free extract (which is based in part on crude protein, ether extract, and crude fibre contents).

Energy levels are of primary importance in balancing feeds, so understanding the chemical nature of feed ingredients should be of primary importance to animal producers. Accurately representing feed composition should be a priority for future research efforts to increase the precision of predicting feed ingredient energy levels and maximising feed utilisation. The use of nutrient terms undefinable chemically will not be helpful in producing prediction equations for energy utilisation.

The case in point is carbohydrate composition represented by CF and NFE in the Weende method. Since NFE is calculated as the difference between the total, 1000 g/kg, and the contents of crude protein, crude fat, ether extract, crude fibre and ash, there must be correlations between these variables. When test compounds are added to any feed, something else must be deleted. Are there any effects of the test compound due to its presence or the absence of whatever it is substituted for?

Choct (2015) summarised the importance of understanding feed carbohydrate chemistry as it relates to energy utilisation, digestive physiology and feeding practices as follows:

The continuing use of crude fibre in feed formulation means that up to a quarter of the feed components, mainly non-starch polysaccharides and oligosaccharides that are lost during acid and alkali extractions, are ignored for ingredients such as soybean meal. Furthermore, the values for acid detergent fibre and neutral detergent fibre are not used for feed formulation. They also do not represent unique classes of chemically defined molecules. In some cases, neutral detergent fibre and acid detergent fibre values do not cover a large proportion of soluble fibre, for example, in leguminous crops that contain a high level of pectic polysaccharides. Non-starch polysaccharides and their associated lignin content represent the true fibre levels in ingredients, and this is the basis from which structural and physicochemical elucidation of fibre can be attained. Only with such understanding will nutritional strategies be applied to target specific fractions/types of fibre in ingredients to produce desired nutritional and health outcomes in pigs and poultry.

This statement clearly outlines the problems associated with the term ‘crude fibre’. The Armidale Method uses the four key components of fibre, i.e. lignin, cellulose, pectin, and hemicellulose separately. In addition, it also presents the detailed breakdowns of other carbohydrates, such as starch, oligosaccharides, and monosaccharides. It is well understood that these different carbohydrate entities have vastly different nutritional and functional characteristics in poultry and other species.

Another important area of concern is crude protein. For the past 100+ years it has been believed that feed crude protein is not required, only amino acid contents are required (Forbes 1924). This is not strictly true (Harper et al. 1970). Animals require 22 ‘essential’ amino acids for protein synthesis. About half of these are dietarily indispensable and required. The other half can be synthesised in situ, but they need a source of amino nitrogen for their synthesis. They are dietarily dispensable, or dietarily nonessential. The nonessential amino acids in the diet, or excesses of the essential amino acids, can supply the amino nitrogen. Therefore, there is a total amount of amino nitrogen from amino acids that is required, or essential. This total, best represented by the sum of the amino acids, is called true protein (Sriperm et al. 2011).

Animal breeding companies often give reference crude protein levels when stating amino acid needs. They recognise that there is no crude protein requirement per se but have not recognised that true protein is easily estimated from feed amino acid levels. True protein then can be used as a proxy for the total amount of amino nitrogen available for the de novo synthesis of the nonessential, or dietarily dispensable amino acids. It cannot be known how many nutritionists use crude protein in their formulations, and how many use some amino acid not available in a purified form as a surrogate to maintain adequate levels of dietary essential and nonessential amino acids.

It is now known that amino acids are required in precise ratios, primarily as precursors for body proteins. Even though in many feeds, methionine is the first limiting amino acid for poultry, lysine has been chosen as a reference amino acid to relate to the required concentrations of the other amino acids and true protein (Alhotan and Pesti 2016). The reason for choosing lysine instead of methionine as the reference amino acid was due to the ease of determination and its relative stability. From a mathematical perspective, it does not really matter which essential amino acid is chosen as long the requirement for one, and the ratios between them are well established.

In the absence of an accurate measure of each amino acid concentration in the feed, the true protein content of feeds, and not crude protein content, gives a much better ideal amino acid balance if the lysine concentration is known. The true protein contents of feed ingredients will be the easiest to implement. It can be found by summing the amino acids present in the ingredients (Sriperm et al. 2011), or it can be closely estimated from the nitrogen content of the ingredient if the precise amino acid composition is not known (RA Alhotan, GM Pesti, L Billard, unpubl. data; Fig. 2).

The true protein concentration of a feed is the best way to represent the requirement for the dietarily dispensable, nonessential, amino acids. In addition, there is evidence that animals will respond to feed nucleotides (Jung and Batal 2012). It is important that the protein and nonprotein nitrogenous compounds be separated when describing feeds and their energetic and other contributions quantitated separately.

The nature of the nonprotein nitrogenous compounds may be important for ingredients like wheat that contain greater than 0.5% choline and betaine. There has been much research on the nitrogen to protein ratios of many ingredients. In the absence of specific data for an ingredient, true protein seems to be closely estimated by 5.6 times the nitrogen content.

The Armidale Method also attempts to improve how dietary fat is presented. It gives fat as neutral and polar lipids, as they differ in their nutritional and functional properties in feed. The average total component value of the ingredients is slightly over 1000 g/kg, at 1030.0 ± 49.5 (Table 2). This may have resulted, at least in part, from counting phospholipids with the lipids and again with crude protein. Or there may be other reasons components add to greater than 1000 g/kg that a comprehensive investigation into the composition of unique samples will discover. That the perfect result, 1000 g/kg, is included within one standard deviation of the observed mean for the preliminary database is a good indication of the Armidale Method’s potential value.

The highest total composition value was 1119 g/kg for triticale (Table 2). Triticale had similar components to the other grains, so there is no obvious reason for its total components to be much higher than the others. It may be that the components of triticale do not add to 1000 g/kg because not all measurements come from the same samples. Feed ingredient databases contain average values from many samples and triticale is known to be quite variable due to its hybrid nature.

Considering the present widespread use of near-infrared spectroscopy (NIRS) technology to estimate feed ingredient composition, the implementation of an improved feed analysis system could happen very quickly. Once chemical parameters of the system are established, ingredient analyses and calibration curves could be developed very quickly, with implementation starting within a matter of months. The system should be available to researchers as well as producers. This would help producers understand if and how research results apply to their feeds and birds and mammals.

Conclusions

Consider that proximate analysis is known to be an inadequate, archaic, description of feeds and feed ingredients: (1) for trading ingredients based on their true value; (2) for predicting the energetic contributions of feed ingredients and balancing feed energy levels; (3) for balancing feeds with respect to protein and the nonessential amino acids. It follows that it is past time for animal producers to develop and refine a new system based on 21st century analytical chemical and nutritional understandings.

The Armidale Method focuses on how each nutrient can be chemically defined, instead of relying on its physical characteristics or the method used to extract it. The Armidale Method is at its initial stage of development and hence it is not advocated as a total replacement of the Weende method. It is hoped that the Amidale Method may serve as a starting point for discussions of appropriate categories and methodologies. It is logical that animal production companies take the lead in this effort since (1) they will be the primary beneficiaries; and (2) they pay, either directly or indirectly, for all animal and poultry nutrition research.

Thomas Kuhn (1970) wrote:

Max Planck, surveying his own career in his Scientific Autobiography, sadly remarked that “a new scientific truth does not triumph by convincing its opponents and making them see the light, but rather because its opponents eventually die, and a new generation grows up that is familiar with it”. (Thomas S. Kuhn, The Structure of Scientific Revolutions)

Kuhn, and Planck, thought paradigm shifts are generational processes. Yet the ideas of practically instantaneous feed analysis by NIRS technology and practically instantaneous global communication by the internet were completely unknown in their times. The next, most important, step to improve animal production efficiency may well be to relegate proximate analyses to the past and replace them with a method based on 21st century feed chemistry analytical techniques. Too many generations have already passed by using technologies that were state of the art in 1864.

Acknowledgements

The author gratefully acknowledges Mingan Choct and Rashed Alhotan for critically reviewing this manuscript.

References

Alhotan RA, Pesti GM (2016) Quantitative estimates of the optimal balance between digestible lysine and the true protein contents of broiler feeds. British Poultry Science 57, 538-550.

| Crossref | Google Scholar | PubMed |

Carpenter KJ, Harper AE, Olson RE (1997) Experiments that changed nutritional thinking. Journal of Nutrition 127, 1017S-1053S.

| Crossref | Google Scholar |

Choct M (2015) Feed non-starch polysaccharides for monogastric animals: classification and function. Animal Production Science 55, 1360-1366.

| Crossref | Google Scholar |

Feedipedia (2024) Animal feed resources information system. Available at http://www.feedipedia.org/ [Accessed 15 April 2024]

Forbes EB (1924) True protein versus crude protein as a basis for computation of feeding standards. Journal of Dairy Science 7, 154-159.

| Crossref | Google Scholar |

Harper AE, Benevenga NJ, Wohlhueter RM (1970) Effects of ingestion of disproportionate amounts of amino acids. Physiological Reviews 50, 428-558.

| Crossref | Google Scholar | PubMed |

Jung B, Batal AB (2012) Effect of dietary nucleotide supplementation on performance and development of the gastrointestinal tract of broilers. British Poultry Science 53, 98-105.

| Crossref | Google Scholar | PubMed |

Krul ES (2019) Calculation of nitrogen-to-protein conversion factors: a review with a focus on soy protein. Journal of the American Oil Chemistry Society 96, 339-364.

| Crossref | Google Scholar |

Mateos GG, Cámara L, Fondevila G, Lázaro RP (2018) Critical review of the procedures used for estimation of the energy content of diets and ingredients in poultry. Journal of Applied Poultry Research 28, 506-525.

| Crossref | Google Scholar |

Mariotti F, Tomé D, Mirand PP (2008) Converting nitrogen into protein--beyond 6.25 and Jones’ factors. Critical Reviews in Food Science and Nutrition 48, 177-84.

| Crossref | Google Scholar | PubMed |

Moss A (2020) Database of the nutrient contents of Australian feed ingredients. AgriFutures Australia Publication No. 20-078. Available at https://agrifutures.com.au/wp-content/uploads/2020/09/20-078.pdf [Accessed 10 November 2023]

Mossé J (1990) Nitrogen-to-protein conversion factor for ten cereals and six legumes or oilseeds. A reappraisal of its definition and determination. Variation according to species and to seed protein content. Journal of Agricultural Food Chemistry 38, 18-24.

| Google Scholar |

Pesti GM, Choct M, Chrystal PV, Bedford MR, Moss AF (2024) Teaching the principles of least-cost poultry feed formulation utilizing the Solver function within a computer software workbook. Poultry Science 103, 103636.

| Crossref | Google Scholar | PubMed |

Richardson C (1888) Methods of analysis of commercial fertilizers, cattle foods, dairy products, sugar, and fermented liquors adopted at the Fifth Annual Convention of the Association of Official Agricultural Chemists, held at the U.S. Department of Agriculture, August 9 and 10. In ‘Bulletin No. 19’. US Department of Agriculture, Division of Chemistry, Washington DC. Available at https://original-ufdc.uflib.ufl.edu/AA00025047/00001 [Accessed 30 April 2024]

Severe JH (2022) A brief and comprehensive history of the development and use of feed analysis: a review. Open Agriculture 7, 837-846.

| Crossref | Google Scholar |

Sosulski FW, Imafidon GI (1990) Amino acid composition and nitrogen-to-protein conversion factors for animal and plant foods. Journal of Agricultural and Food Chemistry 38, 1351-1356.

| Crossref | Google Scholar |

Sriperm N, Pesti G, Tillman PB (2011) Evaluation of the fixed nitrogen-to-protein (N:P) conversion factor (6.25) versus ingredient specific N:P conversion factors in feedstuffs. Journal of the Science of Food and Agriculture 91, 1182-1186.

| Crossref | Google Scholar |

Tkachuk R (1969) Nitrogen-to-protein conversion factors for cereals and oilseed meals. Cereal Chemistry 46, 419-424.

| Google Scholar |

Tkachuk R, Irvine GN (1969) Amino acid compositions of cereals and oilseed meals. Cereal Chemistry 46, 206-218.

| Google Scholar |

Wardeh MF (1981) Models for estimating energy and protein utilization for feeds. PhD thesis, Utah State University, Logan, UT, USA. Available at https://digitalcommons.usu.edu/etd/4556 [Accessed 15 April 2024]

Weihrauch JL, Son YS (1983) Phospholipid content of foods. Journal of the American Oil Chemists Society 60, 1971-1978.

| Crossref | Google Scholar |